Cable Assemblies

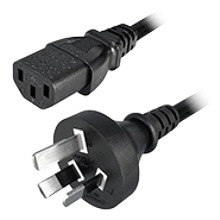

Cable assemblies are groups of cables arranged into a single unit for a particular purpose. These can also be referred to as cable harnesses or wire harnesses. They come in a variety of length and various terminations.

Each cable assembly typically includes wires or cables (for electrical or signal transmission), connectors at the cable ends, and a form of insulation to safeguard the cables against moisture or heat and for health and safety reasons. A sheath or jacket envelops the entire assembly, which provides an additional layer of protection. Wire color coding is also usually used to help with wire identification.

Cable assemblies play an important role in electronic applications. They help with the protection and organization of wires and cables. They also serve as a safety feature for people working with electrical systems.

Cable assemblies are made following some general steps. First, wires are cut to the desired length using specialized wire-cutting machines. Then, the wire ends are stripped to expose their cores. Next, the wires are fitted to the required terminals or connector housings, each with distinct sizes and specifications. Finally, the wires are assembled into a harness, using a workbench or assembly board configured to adhere to design specifications¹. Wire assemblies can either be made by hand or by machine.

Cable assemblies have a wide range of uses in different industries. They are used anywhere where a group of cables are needed for a single connection. These assemblies can be used to transmit either electricity or signal. Some of their common uses include: flat panel displays, navigation systems, computers, telecommunication applications, LEDs, electronics, drones, automobiles, airplanes, and more.